- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Metal 3d Printing Manufacturer, Supplier, Factory

Mudebao is a Metal 3d Printing manufacturer and supplier in China, we have own factory. You may need some high quality and customized products to meet the actual needs of your region.

Hot Products

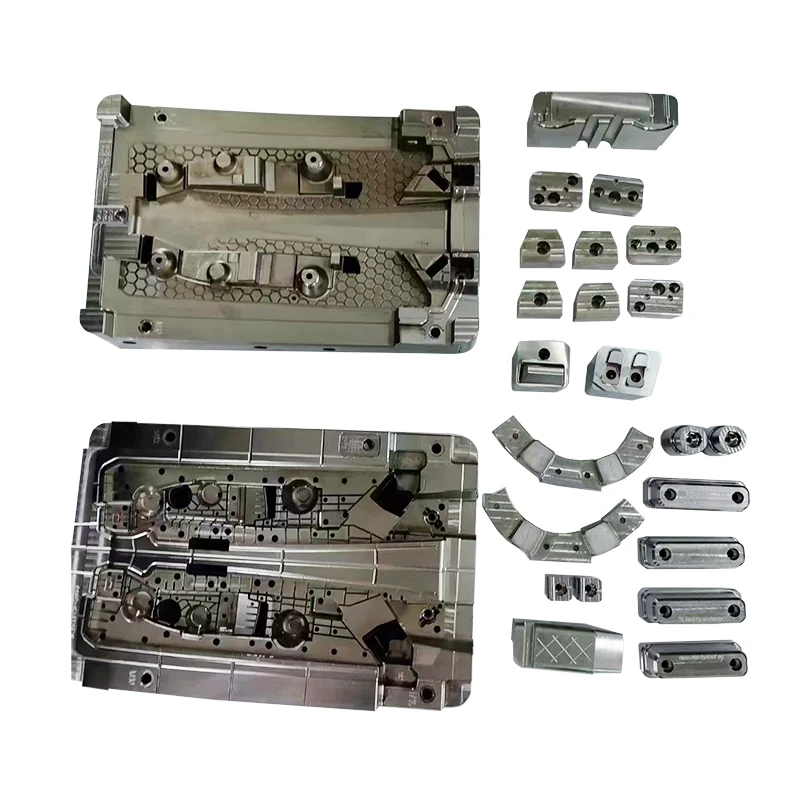

Guides And Other Mould Accessories

The Mudebao Guides and other Mould Accessories are a comprehensive range of precision-engineered components, meticulously crafted by a renowned China-based manufacturer and supplier. Our company specializes in providing high-quality mould accessories that cater to the diverse needs of the plastic injection molding industry.Cavity And Core Completed Machining

Mudebao Cavity and Core Completed Machining, situated in China, is a renowned manufacturer and supplier of precision-engineered cavity and core components for the mold-making industry. Our expertise in this field stems from years of experience and a relentless pursuit of excellence in every aspect of our operations.Aluminium CNC Parts

The Mudebao Aluminium CNC Parts stand as a testament to the pinnacle of precision engineering, emanating from the skilled hands of a pioneering manufacturer nestled in the heart of China. As a reputable supplier with a proven track record, we pride ourselves on offering a comprehensive portfolio of aluminium CNC parts that encapsulate the essence of innovation and precision.Zinc CNC Parts

The Mudebao Zinc CNC Parts represent the epitome of precision and craftsmanship, emanating from a renowned manufacturer and supplier situated in China. As a leading player in the industry, we specialize in offering a comprehensive range of zinc CNC parts that are meticulously designed and manufactured to meet the most stringent quality standards.Precise Inserts

Mudebao Precise Inserts, a leading manufacturer and supplier from China, specializes in crafting high-precision inserts for a wide array of industrial applications. Our commitment to excellence and attention to detail have earned us a reputation for delivering unparalleled quality and reliability in the market.Plastic Injection Mold Base

Mudebao Plastic Injection Mold Base, emerging triumphantly from the epicenter of China's vibrant manufacturing landscape, represents the pinnacle of excellence in the field. This esteemed product is the proud creation of a manufacturer and supplier who has carved a niche for itself through its unyielding dedication to delivering uncompromising quality. Renowned globally for its expertise, the company stands tall as a beacon of innovation, constantly pushing the boundaries of what is possible in the world of plastic injection mold bases.