- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Is Revolutionizing Manufacturing Possible with Precise Inserts: An Innovation in Tooling Technology?

2025-01-07

The rise of precise inserts marks a significant milestone in the advancement of tooling technology. From carbide inserts tailored for CNC lathe machines to CRISPR-based tools enabling precise DNA insertion, the industry is witnessing a wave of innovation that is transforming manufacturing processes across the globe. As these technologies continue to mature and evolve, the possibilities for precise inserts in various industries are boundless.

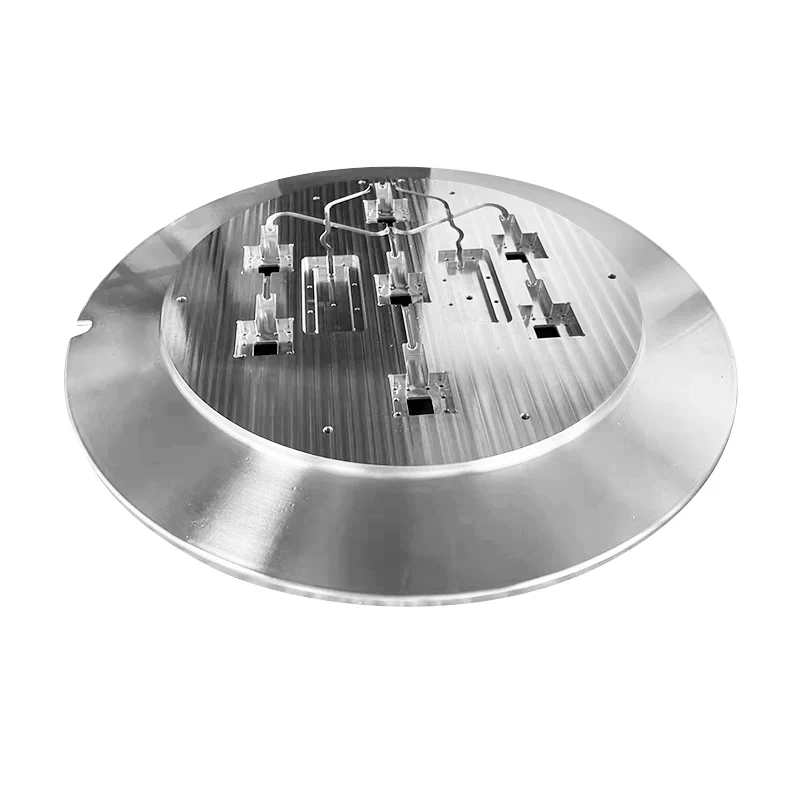

One of the most notable innovations in precise inserts comes from the integration of advanced materials and cutting-edge manufacturing techniques. Carbide inserts, for instance, have been specifically engineered to deliver smooth and clean cuts, thanks to their hardness and precision. Manufacturers like Hao Carbide Co., Ltd. and Henan Drills-King Mining Technology Ltd. are leading the way with their state-of-the-art carbide parting and grooving inserts, tailored for applications in CNC lathe machines. These inserts are designed to work seamlessly with materials such as steel, stainless steel, cast iron, and aluminum, ensuring high-quality results in every production cycle.

The demand for customized solutions has also fueled the growth of precise inserts. With OEM, ODM, and OBM services becoming increasingly popular, manufacturers are now offering tailored inserts that cater to specific industry needs. This customization not only enhances product functionality but also allows for greater flexibility in production processes.

Moreover, the advent of new technologies like CRISPR-based tools is further revolutionizing the world of precise inserts. The PASTE tool, developed by scientists at the Massachusetts Institute of Technology, demonstrates the potential of programmable insertion of DNA sequences. This tool combines the precise targeting of CRISPR-Cas9 with the integrases, enabling the precise insertion of large DNA sequences in targeted sites without causing double-stranded DNA breaks. While this innovation may seem unrelated to manufacturing at first glance, it underscores the broader trend of precision and accuracy being prioritized across various industries.

In the plastics processing industry, precise inserts are playing a crucial role in achieving higher functional integration in a single production step. The Insert Technology allows for the processing of plastics with metal inserts, significantly enhancing the overall performance of the final product. However, high loads during insert molding can often lead to insert failure. To address this challenge, a newly developed calculation method has been introduced, allowing for the accurate prediction of real stresses in the insert, thereby minimizing the risk of failure.

As the manufacturing industry continues to evolve, the demand for precise inserts is expected to surge. Manufacturers are increasingly recognizing the value of investing in high-quality tooling technology to stay ahead of the competition. With ongoing innovations in materials, manufacturing techniques, and customization services, precise inserts are poised to become a staple in the manufacturing sector, driving efficiency, accuracy, and productivity to new heights.