- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What innovations and advancements have been seen in CNC machining?

2024-12-13

The CNC machining industry is in the midst of a transformative period, marked by technological advancements, sustainable practices, and collaborative innovations. As these trends continue to unfold, the future of CNC machining looks promising, with endless possibilities for growth and development.

The world of manufacturing is constantly evolving, and CNC (Computer Numerical Control) machining stands at the forefront of this progression. Recent developments in this sector have not only refined traditional processes but also paved the way for groundbreaking innovations that are reshaping industries across the globe.

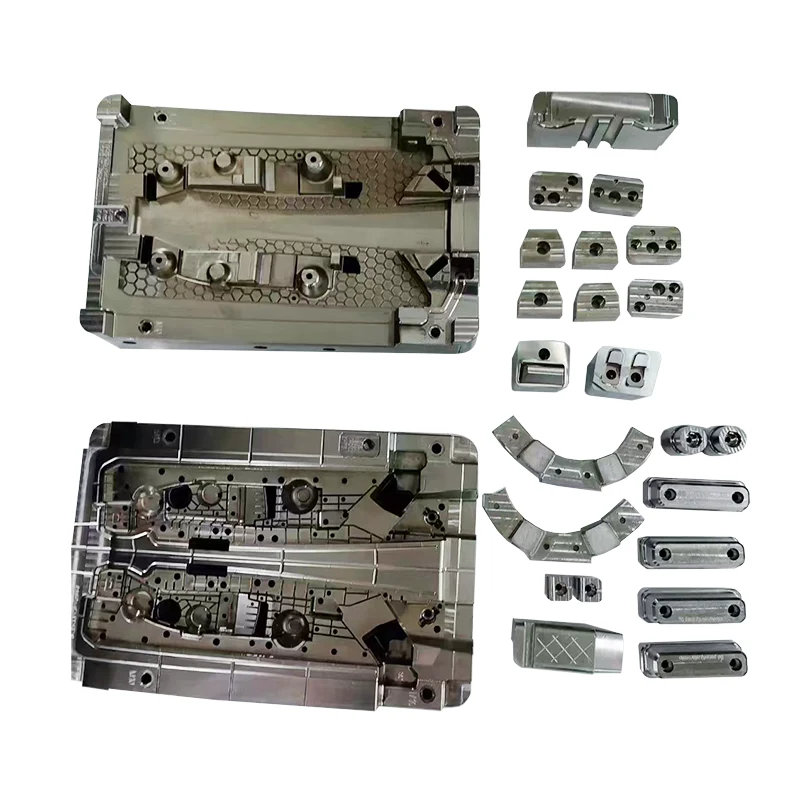

Advancements in CNC Machine Technology

One of the most significant advancements in CNC machining is the integration of artificial intelligence (AI) and machine learning algorithms. These intelligent systems are capable of optimizing toolpaths, predicting machine wear, and adjusting parameters in real-time to minimize errors and maximize efficiency. By leveraging AI, manufacturers are now able to achieve unprecedented levels of precision and productivity.

Moreover, the advent of multi-axis CNC machines has revolutionized complex part production. These advanced machines can perform intricate operations on all sides of a workpiece simultaneously, reducing setup times and eliminating the need for multiple machines or setups. This capability has significantly shortened production cycles and lowered overall costs.

Sustainable Manufacturing Practices

In response to the growing emphasis on sustainability, the CNC machining industry is increasingly adopting eco-friendly practices. Manufacturers are investing in energy-efficient machinery and recycling programs to minimize waste and reduce their carbon footprint. Additionally, the use of biodegradable coolants and lubricants is becoming more widespread, further enhancing the environmental profile of CNC operations.

Collaborative Robotics in CNC Machining

Collaborative robots, or cobots, are another exciting development in the CNC machining sector. These robots are designed to work safely alongside human operators, performing tasks that are dangerous, repetitive, or ergonomically challenging. By incorporating cobots into their workflows, manufacturers can improve safety, enhance productivity, and reduce labor costs.

The Role of Additive Manufacturing

While CNC machining remains a cornerstone of subtractive manufacturing, the integration of additive manufacturing (AM) technologies, such as 3D printing, is creating new possibilities. Hybrid manufacturing systems that combine CNC machining and AM allow for the production of complex parts with both subtractive and additive features, offering unparalleled design flexibility and performance.

Market Expansion and Global Trends

The global CNC machining market is experiencing significant growth, driven by demand from industries such as aerospace, automotive, medical, and electronics. As these sectors continue to innovate, they require more sophisticated and customized components, which CNC machining is well-positioned to provide.

Furthermore, the rise of precision engineering and the increasing demand for high-tolerance parts are fueling the adoption of advanced CNC machining technologies. Manufacturers are continually investing in research and development to stay ahead of the curve and meet the evolving needs of their customers.